Welcome to Creative Laser Craft, your trusted partner in the world of precision cutting and crafting. With a legacy spanning over 8 years, we have been at the forefront of the laser and CNC cutting industry in Delhi, India.

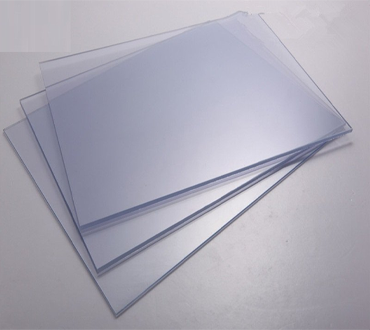

PET Sheet

PET Sheet

PET sheets, i.e. Polyethylene terephthalate sheets, are famous for their various properties used in various industries. These sheets are known for their high transparency, specific strength, and resistance to chemicals. The process of making PET sheets involves extruding the polymer, resulting in a material with a smooth surface and excellent dimensional stability. Due to its transparency and durability, PET sheets are commonly used in applications such as packaging, graphic arts, and signage. Whether made from clear packaging materials or vibrant graphic displays, PET sheets provide a convincing and visually appealing solution for a variety of purposes.

About Material:

The material used in PET (polyethylene terephthalate) sheet has defined its special and various properties. PET is a strong and lightweight thermoplastic polymer that is widely used for its versatility. In the manufacturing process, PET is extruded and then cooled to form flat sheets. This material has excellent transparency, allowing light to pass through with little distortion. Known for its resistance to impact, chemicals and moisture, PET sheet is a preferred choice across various industries. Its recyclability further increases its environmental attractiveness. PET sheets are used in packaging, signage and graphic arts due to their clarity and ease of manufacturing. Whether it's for retail displays, protective covers, or creative projects, PET sheets are renowned for their clarity, flexibility, and adaptability.

Type of Material

The type of material used in PET (polyethylene terephthalate) sheet plays an important role in determining its specific properties and methods. PET sheets are made from a strong thermoplastic polymer known for its versatility and flexibility. The extrusion process is used to create flat sheets from PET, maintaining uniformity and consistency in their thickness. PET sheets come in various forms, such as transparent, translucent, and colored variants, offering a spectrum of options for different applications. Notable features of this material include excellent transparency, impact resistance, chemical flexibility and moisture resistance. This versatility makes PET sheet suitable for a wide range of applications from packaging to medical signage, graphic arts and beyond. The different types of PET sheet materials take into account the specific requirements in industries where clarity, durability and adaptability are of utmost importance.

Transparent PET Sheets:

Transparent PET sheets are characterized by their unparalleled clarity, which allows light to pass through without distortion. Since visibility and aesthetics are extremely important, these sheets are used in packaging, displays and creative projects.

Colored PET Sheets:

Colored PET sheets come in vibrant colors, providing a visually appealing option. Whether used for artistic endeavors, signage, or decorative elements, these sheets add colorful light to a variety of applications.

Advantage after other materials

PET sheets have a distinct identity compared to other materials, making them the preferred choice in a variety of applications. Some key benefits include

Clarity and Transparency:

PET sheets provide exceptional clarity and transparency giving crystal-clear views. This advantage is especially important for applications where visibility is important, such as displays, packaging and signage.

Lightweight and Durable:

In addition to being lightweight, PET sheets are designed to be strong and easy to handle. This makes them suitable for applications ranging from artistic projects to medical industrial uses.

Chemical and Moisture Resistance:

PET sheets show excellent resistance to chemicals and moisture, ensuring longevity and reliability in a variety of environments. This feature enhances their use in applications requiring resistance to changing factors.

Versatility in Forms:

Available in various forms such as transparent, translucent and colored variants, PET sheets are suitable for a wide spectrum of aesthetics and functionality. This versatility further increases their suitability for diverse industries.

Use Case of Material

PET sheets are extensively used in various industries due to their versatile properties. Some prominent cases include:

Packaging Industry:

PET sheets are widely used in the packaging industry due to their clarity, durability and light weight. These ensure product visibility and protection, making them a popular choice in packaging various consumer goods.

Graphic Arts and Signage:

PET sheets are preferred in graphic arts and signage for their exceptional transparency and color retention. These provide a clear canvas for vibrant graphics and signage displays that lack visual appeal.

Automotive Sector:

The automotive industry uses PET sheet for applications such as interior components and signage. Their lightweight yet strong nature makes them suitable for creating durable and visually appealing automotive elements.

Retail Displays:

PET sheets are widely used in retail displays due to their transparency and adaptability. These contribute to creating attractive and informative displays that are used to showcase products in a retail environment.

Medical Packaging:

Due to their resistance to chemicals and moisture, PET sheets are used in medical packaging. These provide a hygienic and protective solution for packaging medical devices and supplies.

Why Choose Creative Laser Craft

The creative laser craft you need for your PET sheet provides you with many benefits. Here are some of the special reasons that make us different in choosing:

Precision Laser Cutting:

Creative Laser Craft specializes in precise laser cutting technology, which ensures that intricate and precise designs are created on PET sheets. Our state-of-the-art machinery delivers impeccable results, meeting the highest quality standards.

Customization Expertise:

We specialize in creating custom, tailor-made PET sheet solutions to meet your specific needs. Be it unique designs or specific dimensions, our team brings your ideas to life with precision.

Wide Range of Finishes:

Creative Laser Craft offers a different range of finishes for PET sheets, helping you choose the right aesthetic for your project. From glossy to matte, we offer options that are suitable for a variety of applications.

Commitment to Quality:

Our commitment to quality is unwavering. Each PET sheet undergoes rigorous quality checks to ensure durability, clarity and performance that meets and exceeds industry standards.

Creative Solutions for Industries:

Whether you are in packaging, signage, automotive, or any other industry, Creative Laser Craft provides creative solutions for the specific needs of your industry, ensuring optimal performance.

.png)