Welcome to Creative Laser Craft, your trusted partner in the world of precision cutting and crafting. With a legacy spanning over 8 years, we have been at the forefront of the laser and CNC cutting industry in Delhi, India.

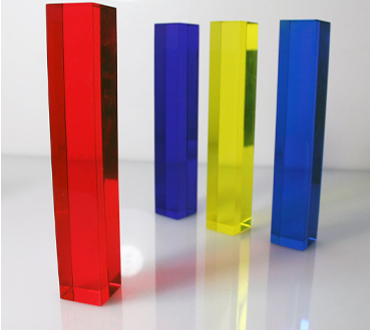

Casted Acrylic

Casted Acrylic

Cast acrylic, also called extruded acrylic, is popular in a variety of applications due to its unique manufacturing process. In the production of cast acrylic, liquid acrylic is poured into molds and then set to form sheets. This type of method yields material that comes with exceptional clarity and minimal internal stress. Cast acrylic sheets are known for their transparency, giving them excellent optical clarity. Their surface is smooth, making them suitable for detailed carving, intricate designs and display. Whether used in signage, artistic creations or architectural elements, cast acrylic works great in conveying a sense of sophistication and modernity.

About Material:

The material used to make cast acrylic, also known as extruded acrylic, plays an important role in defining its characteristics. Cast acrylic is produced through a special manufacturing process in which liquid acrylic is poured into molds and then allowed to set, producing flat and transparent sheets. This process involves adding high quality acrylic polymers that contribute to the material's unparalleled clarity, allowing light to pass through it with less distortion. This type of method produces sheets with minimal internal stress, which ensures the stability and durability of the material. This makes cast acrylic an ideal choice for applications that require optical precision, such as signage, artistic compositions and architectural elements, where the material's transparency and finish shine.

Type of Material

The type of material used in cast acrylic, also known as extruded acrylic, contributes significantly to its various applications and specifications. Cast acrylic is made primarily from high-quality acrylic polymers, carefully selected for their optical properties. These polymers undergo a special manufacturing process in which liquid acrylic is poured into a mold and then allowed to set, resulting in flat and transparent sheets. The physical characteristics of cast acrylic include exceptional clarity, minimal internal stresses and a smooth surface. These special features make it suitable for a wide variety of applications, such as signage, artistic compositions and architectural elements. The material's versatility and visual appeal comes from its carefully chosen composition, making cast acrylic the preferred choice for projects that demand both precision and aesthetics.

Casted Acrylic Sheets:

Cast acrylic sheet is produced through a casting process, resulting in a material that is known for its superior optical clarity. These sheets exhibit minimal internal stresses, providing excellent resistance to tearing and tearing.

Thermoplastic Properties:

Cast acrylic is a thermoplastic, meaning it becomes flexible when heated and can be molded into different shapes. This property increases its versatility, allowing the creation of complex designs and forms.

UV Resistance:

Cast acrylic is naturally UV resistant, making it suitable for both indoor and outdoor applications. This resistance ensures that the material retains its clarity and does not yellow or degrade when exposed to sunlight.

Chemical Resistance:

This material has good chemical resistance, making it suitable for applications where contact with a wide variety of chemicals may occur. This characteristic expands their use in diverse industries.

Advantage after other materials

Cast acrylic has a distinct advantage over other materials, making it a preferred choice in a variety of applications. One of its main characteristics is its unparalleled optical clarity, which allows light to pass through with little distortion. Unlike many competing materials, cast acrylic exhibits minimal internal stresses during production, ensuring flat and stable sheets. This inherent stability affects its length and durability, preventing it from cracking and yellowing over time. Additionally, the smooth surface of cast acrylic facilitates detailed engraving and intricate designs. Its versatility, impact resistance, and practical operation in harsh environmental conditions further enhance its superiority. Whether it's used in signage, artistic creations, or architectural elements, the benefits of cast acrylic shine through, making it an optimal choice for projects that demand both quality and longevity.

Optical Clarity:

Cast acrylic comes with high optical clarity, giving a crystal-clear look. This makes it an ideal choice for use cases where visual aesthetics are paramount.

Impact Resistance:

An important advantage of cast acrylic is its exceptional impact resistance. It can withstand impacts better than traditional glass, reducing the risk of breakage.

Lightweight Nature:

Cast acrylic is lighter than glass, making it easier to handle and install. This special feature becomes very important in our applications where weight becomes very important.

Versatility in Design:

The thermoplastic nature of cast acrylic provides versatility in design. It can be easily molded into different shapes, allowing intricate and complex designs to be created.

UV Stability:

Cast acrylic has excellent UV stability, ensuring that it will not degrade or yellow when exposed to sunlight. This UV resistance improves its longevity in outdoor applications.

Use case of material

Cast acrylic is widely used in industry due to its diversity and versatility. In the signage industry, cast acrylic is used extensively due to its optical clarity, which can create vivid and attention-grabbing displays. In the field of imaginative creations, its smooth surface and durability make it an ideal canvas for intricate designs and sculptures. Architectural elements take advantage of the capabilities of cast acrylic to provide both structural integrity and aesthetic appeal. The retail sector uses its clarity for product display, providing attractive presentations to customers. Additionally, the automotive industry uses cast acrylic for smooth and durable interior components. Its application has expanded to medical devices, lighting fixtures and other fields. Its wide range of use cases across industries shows the adaptability and effectiveness of cast acrylic to meet various requirements.

Retail Displays:

Cast acrylic is used extensively in retail displays for its optical clarity and increased visibility of products. Its lightweight nature makes it suitable for creating attractive and durable display units.

Signage and Branding:

The material's exceptional optical clarity has made it a favorite for use in signage and branding. Cast acrylic signage offers a clean and professional look, making it ideal for displaying logos and information.

Automotive Components:

In the automotive industry, cast acrylic is used for various components such as light covers, instrument panels, and interior trims. Its impact resistance and optical clarity contribute to superior safety and aesthetics.

Architectural Glazing:

Cast acrylic is used in architectural glazing because of its clarity and lightness. It is an alternative to glass, providing flexibility in design while maintaining transparency.

Art and Sculptures:

Cast acrylic is used in architectural glazing because of its clarity and lightness. It is an alternative to glass, providing flexibility in design while maintaining transparency.

Why choose Creative Laser Craft

Cast acrylic holds a distinct advantage over other materials, making it a preferred choice in a variety of applications. A major advantage lies in its exceptional optical clarity, which allows the transmission of light with minimal distortion. Unlike some competing materials, cast acrylic exhibits minimal internal stresses during production, ensuring flat and stable sheets. This inherent stability contributes to its longevity and durability, making it resistant to cracking and yellowing over time. Additionally, the smooth surface of cast acrylic facilitates detailed engraving and intricate designs. Its versatility, impact resistance and resistance to harsh environmental conditions further enhance its superiority. Whether used in signage, artistic creations, or architectural elements, the advantages of cast acrylic shine through, making it an optimal choice for projects that demand both quality and longevity.

State-of-the-Art Laser Technology:

We use state-of-the-art laser technology to create intricate and precise cuts on cast acrylic. This ensures that your final product is of high quality including accurate details.

Customization Options:

At Creative Laser Craft, we understand the importance of uniqueness. We give you the opportunity to choose from many customization options, allowing you to give personality to your cast acrylic projects according to your special needs and preferences.

Experienced Craftsmanship:

Our team is made up of skilled and experienced artists who have in-depth knowledge of working with cast acrylic. Their expertise ensures that your projects are completed smoothly and meet high standards.

Attention to Detail:

We pay attention to detail on every project. Whether it's signage, retail displays, or lacquered pieces, our honest approach guarantees that each piece is created with care and attention.

Timely Delivery:

We value your time, and our determination to deliver on time is reflected here. We handle your cast acrylic projects efficiently, ensuring that you receive finished products within the stipulated time.

.png)