Welcome to Creative Laser Craft, your trusted partner in the world of precision cutting and crafting. With a legacy spanning over 8 years, we have been at the forefront of the laser and CNC cutting industry in Delhi, India.

ACP Sheet Cutting

ACP Sheet Cutting

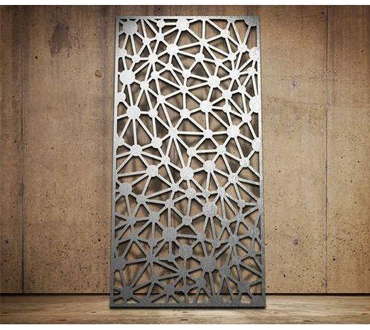

ACP (Aluminium Composite Panel) Sheet Cutting is a precision-oriented process that transforms ACP sheets into customized designs for various applications. Our advanced CNC technology ensures clean and precise cuts on ACP sheets, which helps in creating intricate patterns, sleek facades, and vertical signage. ACP sheets, renowned for their light weight and weather resistance, become a versatile medium for architectural and decorative purposes through our cutting services.

Our skilled artisans are adept at enhancing the aesthetic appeal of ACP sheets through precise cuts and innovative designs. Whether you're planning exterior cladding, signage, or interior decoration, our ACP sheet cutting services provide the perfect blend of functionality and visual appeal. Experience the seamless integration of technology and craftsmanship with our ACP sheet cutting solutions.

About Material:

Material type ACP (Aluminum Composite Panel) plays an important role in the process of sheet cutting. ACP sheets are made of thin aluminum layers that sandwich a core material, which is often made of polyethylene. This mixture creates a lightweight but durable material, making ACP sheets suitable for a variety of applications.

Aluminum Layers:

The outer layers of ACP sheets are made of aluminum, which gives the material water repellency, weather resistance, and a sleek, modern appeal. Aluminum layers contribute to the strength and longevity of the ACP sheet material.

Polyethylene Core:

The core material between the aluminum layers is typically polyethylene, which contributes to the lightweight nature of the material. Polyethylene is known for its thermal insulation properties, it follows that ACP sheets provide good heat resistance.

Versatility:

ACP sheet cutting allows a wide range of designs, shapes and sizes to be created due to the versatility of the material. This makes ACP sheets suitable for architectural cladding, signage, interior decoration and other applications where a combination of aesthetics and durability is essential.

Type of Material

ACP (Aluminium Composite Panel) sheet cutting involves combining different materials to achieve a consistent and durable result. Here the type of material and application for ACP sheet cutting, know the application option:

Aluminum Layers:

Material Details: Two thin aluminum layers of ACP sheet are joined to form the marine surface.

Applications: Aluminum layers provide waterproofing and weatherproofing, such as ACP sheets used for marine cladding, signage and architectural elements.

Polyethylene Core:

Material Details: The core material between the aluminum layers is usually made of polyethylene.

Applications: Polyethylene is known for its light weight and thermal insulation properties, making ACP sheets suitable for interior applications, such as partitions and decorative panels.

PVDF Coating:

Material Details: Some ACP sheets come with PVDF (polyvinylidene fluoride) coating, which improves their durability and color fastness.

Applications: PVDF-coated ACP sheets are preferred for projects that require long-term color vibrancy, such as marine signage and architectural accents.

Fire-Retardant Core:

Material Details: ACP sheets that come with a fire retardant core improve fire protection properties.

Applications: These sheets are used in areas where fire safety is important, such as commercial buildings, traffic intersections and public service areas.

Wooden Finish ACP:

Material Details: ACP sheets that look like wood without compromising the aesthetic benefits of wood.

Applications: Wooden finish ACP sheets are mainly used in interior design to provide a warm and classic look.

Digital Printing Surface:

Material Details: ACP sheets that come with a surface suitable for digital printing.

Applications: Surface suitable for digital printing on ACP sheet, used for customized graphics projects, such as signage, branding and art installations.

Advantage after other materials

Opting for ACP (Aluminium Composite Panel) sheet cutting offers several benefits that set it apart from alternative materials. Here's a detailed look at why ACP sheets have a competitive edge:

Durability and Robustness:

Description: ACP sheets are renowned for their durability and strength, ensuring resilience against various environmental factors.

Advantages: The strong structure of ACP sheets guarantees long-term performance, making them suitable for both interior and exterior applications.

Design Versatility:

Description: ACP sheet cutting allows complex designs, patterns and shapes, providing unparalleled flexibility in aesthetic customization.

Advantages: Versatility in design enables ACP sheets to meet a wide spectrum of applications, from architectural cladding to artistic installations.

Weather Resistance:

Description: ACP sheets exhibit exceptional weather resistance, maintaining their appearance and structural integrity even in challenging weather conditions.

Advantages: This flexibility makes ACP sheets the preferred choice for exterior applications, such as signage and building facades.

Lightweight Composition:

Description: ACP sheets have a lightweight structure, which facilitates easy operation and quick installation.

Advantages: Lightweight nature contributes to efficient and quick installation processes, thereby saving time and labor costs.

Thermal Insulation Properties:

Description: The polyethylene core within the ACP sheet provides effective thermal insulation properties.

Advantages: This feature makes ACP sheets suitable for applications where temperature control and insulation are important, especially in interior spaces.

Versatile Applications:

Description: ACP sheets are used in many areas from architectural projects to decorative elements and signage.

Advantages: Their adaptability allows ACP sheets to be seamlessly integrated into various projects, enhancing both functionality and aesthetics.

Use case of material

ACP (Aluminium Composite Panel) Sheet Cutting finds diverse applications across industries due to its versatility and unique properties. Here's a glimpse of how ACP sheet cutting is used in various fields:

Architectural Cladding:

Description: ACP sheets are extensively used in architectural cladding to enhance the aesthetics of buildings.

Uses: This application is prevalent in the construction industry, providing a modern and visually appealing appearance to structures.

Signage and Branding:

Description: ACP sheets serve as a popular material for creating signage and branding elements.

Uses: Industries, especially retail and commercial sectors, use ACP sheet cutting for durable and attractive signs that promote brand visibility.

Interior Design:

Description: ACP sheets are used in interior design for applications such as wall panels, partitions and decorative elements.

Usage: Various industries, including hospitality and residential sectors, take advantage of ACP sheet cutting to achieve modern and stylish interior spaces.

Art and Exhibitions:

Description: ACP sheet cutting is adopted in the art world to create exhibition displays and artistic installations.

Uses: Art galleries, museums and exhibition venues use ACP sheets to achieve complementary visual displays of various artworks.

Furniture Manufacturing:

Description: ACP sheets are incorporated in furniture manufacturing to create modern and innovative furniture pieces.

Uses: The versatility of ACP sheet cutting allows furniture designers to create unique and contemporary pieces in a variety of industries.

Why choose Creative Laser Craft

Creative Laser Craft has emerged as the top choice for ACP (Aluminium Composite Panel) sheet cutting, offering cutting-edge technology and customization expertise. Our state-of-the-art laser cutting ensures precise and intricate details while meeting the most demanding specifications. Attention to detail guarantees flawless results while setting industry standards. With a commitment to timely delivery and use of high quality ACP sheets, we assure durability and longevity in the finished products. Our experienced team, well-versed in the intricacies of ACP sheet cutting, ensures that your projects are in expert hands. Choose Creative Laser Craft for precision, customization and reliable ACP sheet cutting services that effortlessly turn your dreams into reality.

Precision Technology:

Creative Laser Craft utilizes state-of-the-art technology, specifically laser cutting, for ACP sheet cutting, ensuring that each cut is executed with precision and allowing intricate details in the finished products.

Customization Expertise:

Creative Laser Craft specializes in providing customized solutions for ACP sheet cutting. The team tailors the cutting process to meet the specific design requirements and unique objectives of each project.

Attention to Detail:

The company emphasizes attention to detail throughout the ACP sheet cutting process, ensuring that each cut is executed with accuracy and precision, meeting the highest standards in the industry.

Timely Delivery:

Creative Laser Craft understands the importance of deadlines in project delivery. The team has efficient processes to ensure that ACP sheet cutting projects are completed and delivered on time.

Quality Materials:

The company uses high quality ACP sheets and materials for the cutting process, ensuring that the finished products not only meet design specifications but also exhibit durability and longevity.

Experienced Team:

Creative Laser Craft has an experienced team of professionals with wide expertise in ACP sheet cutting. The team members are skilled and knowledgeable about the intricacies of the cutting process.

.png)